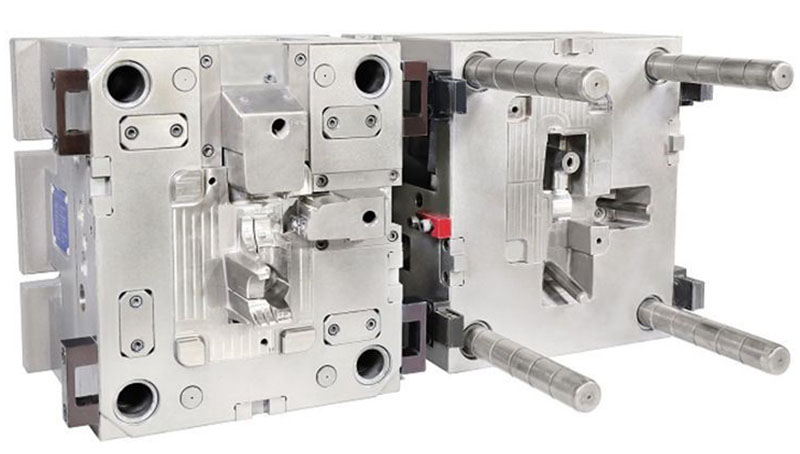

The thickness of dynamic and fixed moulds of plastic injection moulds depends on the size and structure of the plastic parts. In principle, the fixed mould should be as small as possible, while the dynamic mould should be as thick as possible.

The main reason for making the fixed mould as small as possible is that it can reduce the length of the main channel, reduce the exhaust burden of the plastic mould and shorten the moulding cycle. In addition, because the front mould is installed on the injection moulding machine, it is close to the injection moulding machine, so there is no deformation after the production.

The main reason for making the mould as thick as possible is to increase the strength and stiffness of the mould. Of course, the thicker the plastic mould, the higher the production cost will be, worth considering. For the case of too many ejectors and no way to increase the column, the thickness of the back mould should be thickened by about 10mm.

Compared with the original plastic, the reinforced plastic can have many performance improvements. However, there are also some disadvantages of the process.

These should be understood and understood when we use.

1. Poor flowability. The melt index of reinforced plastics is 30% to 70% lower than that of ordinary materials, and it is easy to underfill the situation.

2.The moulding shrinkage of peal plastic is small, and the shrinkage of plastic will be significantly reduced. However, anisotropy is added, such as small shrinkage in the place of feed opening, and large shrinkage in the distance, the plastic parts are easy to produce deformation. Therefore, it is much more difficult for plastic mould design and product injection.

3. the plastic mould release difficulty increases, wear and tear increases, so the plastic mould processing release slope should be designed to be larger. 4. the treatment agent on the surface of the reinforced plastic easily volatilized into gas, must be discharged, otherwise it is easy to melt bad and other problems.

Reinforced plastic is more difficult to inject compared with ordinary plastic. From the time of plastic injection mould design should take into account the following process problems and difficulties.

Post time: May-30-2022